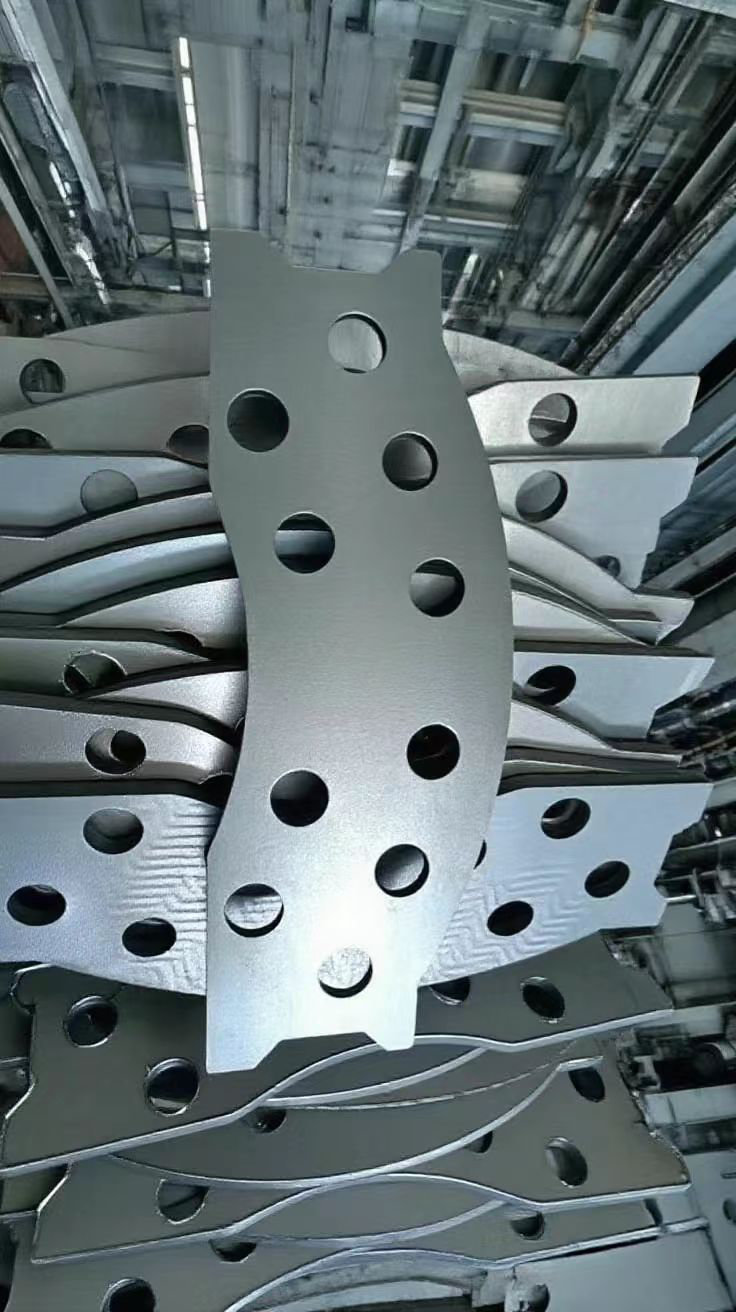

Product Positioning: Core Support Unit for Arc-Shaped Systems

As both the structural framework for drum brake systems and a critical connecting component for arc-shaped transmission mechanisms, the Steel Backing Plate 1108 focuses on “high-strength load bearing + precision adaptation + industrial mass production”, providing stable and efficient arc-shaped connection solutions for automotive, construction machinery, and industrial equipment.

Core Features: Multi-dimensional Construction of Industrial-Grade Quality

1. Materials & Processes: Foundation of Durability

- Base Material Selection: Utilizing high-strength alloy structural steel (such as 40Cr, customizable 65Mn) with tensile strength reaching 600-800MPa, excellent anti-fatigue and anti-deformation capabilities, suitable for high-frequency impact working conditions.

- Machining Precision: Through CNC laser cutting + die punching, achieving hole diameter tolerance ±0.05mm and hole position deviation <0.1mm, smooth hole walls without burrs, ensuring “zero-gap” assembly.

- Surface Treatment: Optional galvanizing (salt spray test ≥480h), blackening (wear coefficient improved by 30%), or electrophoretic coating (enhanced weather resistance) to resist corrosion and wear, extending service life.

2. Structural Design: Dual Optimization of Mechanics and Adaptation

- Arc-shaped Bionic Design: Precisely conforms to drum brake chambers/arc transmission paths, with arc curvature optimized through finite element analysis, reducing stress concentration by 40% and minimizing deformation risks.

- Multi-hole Matrix Layout: Multi-specification holes (compatible with M6~M10 fasteners) supporting “positioning + fixing” integrated assembly, flexibly accommodating friction linings, pins and other components while simplifying installation processes.

- Edge Processing: Chamfering and deburring treatment (chamfer R≥0.5mm) prevents assembly scratches and improves production line operational efficiency.

Application Scenarios: Cross-field Arc Connection Solutions

- Automotive Braking: Serves as drum brake shoe framework, supporting friction linings and ensuring stable braking performance under complex road conditions.

- Construction Machinery: Compatible with brake modules for loaders and forklifts, or as arc transmission components in hydraulic systems, supporting reliable operation under heavy-duty conditions.

- Industrial Automation: Positioning connectors for arc conveyor lines and rotating mechanisms, facilitating modular equipment construction and rapid maintenance.

Industrial Advantages: Breakthrough in Efficiency and Cost

- Batch Consistency: Smart production lines achieve “same precision for ten thousand pieces”, reducing assembly and debugging time by 50% and lowering bulk procurement costs by over 25%.

- Customization Response: Supports customization of hole positions, arc radius, and materials, delivering custom solutions within 72 hours to quickly match non-standard requirements.

- Full-chain Quality Control: From raw material testing to finished product inspection, comprehensive quality management with third-party mechanical performance test reports provided; after-sales response ≤24 hours.

Product Core Value

The Steel Backing Plate 1108 focuses on “precise load bearing, flexible adaptation, industrial mass production” as its core value, thoroughly solving arc transmission/brake system challenges of “difficult adaptation, short service life, high costs”, helping customers create more reliable and efficient equipment solutions.

Technical Specifications Summary

| Specification | Value |

|---|---|

| Model | 1108 |

| Material | High-strength Alloy Steel (40Cr, 65Mn Optional) |

| Tensile Strength | 600-800MPa |

| Hole Diameter Tolerance | ±0.05mm |

| Hole Position Deviation | <0.1mm |

| Surface Treatment Options | Galvanizing / Blackening / Electrophoretic Coating |

| Galvanizing Salt Spray Test | ≥480h |

| Fastener Compatibility | M6~M10 |

| Edge Chamfering | R≥0.5mm |

| Custom Solution Time | 72 hours |

| After-sales Response | ≤24 hours |

Key Performance Advantages

- Ultra-High Precision: ±0.05mm hole diameter tolerance for perfect component fit

- Superior Strength: 600-800MPa tensile strength for demanding applications

- Advanced Surface Protection: Multiple coating options with up to 480h corrosion resistance

- Optimized Arc Design: 40% stress concentration reduction through FEA optimization

- Rapid Customization: 72-hour custom solution delivery

- Comprehensive Support: Third-party testing reports and 24-hour response service

Manufacturing Excellence

- Smart Production: Automated systems ensuring consistent quality across high volumes

- Quality Assurance: Full traceability from raw materials to finished products

- Cost Efficiency: 25%+ reduction in bulk procurement costs through optimized manufacturing

- Flexible Solutions: Adaptable to both standard and non-standard requirements